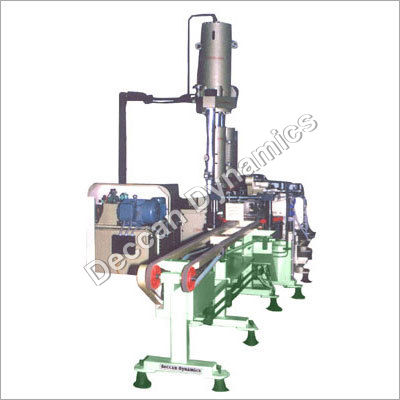

துருக்கியில் வெல்டிங் மின்முனையானது ஆலை

2500000 INR/Unit

தயாரிப்பு விவரங்கள்:

- கூலிங் சிஸ்டம் Water cooled systems for critical units

- எடை Approx. 10,000 kg

- டிரைவ் வகை Electric motor driven

- கட்டுப்பாட்டு அமைப்பு PLC based intelligent control system

- ஆட்டோமேஷன் தரம் Semi-Automatic / Fully Automatic options available

- பொருள் Mild steel, stainless steel contact parts

- அளவு Medium & Large industrial setup

- மேலும் பார்க்க கிளிக் செய்யவும்

X

துருக்கியில் வெல்டிங் மின்முனையானது ஆலை விலை மற்றும் அளவு

- 1

- அலகுகள்/அலகுகள்

- அலகுகள்/அலகுகள்

துருக்கியில் வெல்டிங் மின்முனையானது ஆலை தயாரிப்பு விவரக்குறிப்புகள்

- <80 dB

- 380V / 415V, 3 Phase, 50-60 Hz

- Ambient to 60°C

- 15-30 meters/min (adjustable)

- High productivity, reliable operation, modular construction, low maintenance

- 1200 kg/shift or up to 10 ton/day

- Fabrication shops and welding electrode manufacturing industries

- Continuous and batch type electrode plant

- Mild steel, stainless steel contact parts

- Medium & Large industrial setup

- Semi-Automatic / Fully Automatic options available

- PLC based intelligent control system

- Water cooled systems for critical units

- Approx. 10,000 kg

- Electric motor driven

துருக்கியில் வெல்டிங் மின்முனையானது ஆலை வர்த்தகத் தகவல்கள்

- 1 மாதத்திற்கு

- 1 மாதங்கள்

தயாரிப்பு விளக்கம்

Specification

- Production Capacity 21000 kg per hour

- Automation Grade Semi-Automatic

- Phase 3 Phase

- Material MS ( Body )

- Power Source Electric

- Voltage 440V

- Surface Finishing Color Coated

- Country of Origin Made in India

- Motor Power 100 HP

Advanced Production Flexibility

Catering to changing industry demands, this welding electrode plant supports both batch and continuous production models. Customizable electrode diameter and length ranges offer high adaptability for diverse manufacturing needs. The intelligent PLC control system ensures consistent quality and automation, while adjustable speed settings keep production rates optimized.

Efficiency and Low Maintenance

Featuring a water-cooled system for critical units, the plant is engineered for maximum uptime and minimal operational interruptions. Its powder-coated or painted surfaces provide durability and ease of cleaning, while mild steel and stainless steel contact parts ensure corrosion resistance and longevity with minimal maintenance required.

Versatile Raw Material Compatibility

From MS wire to complex chemical mixes, the plant seamlessly handles a spectrum of raw materials. This compatibility allows manufacturers to produce a wide array of welding electrodes, ensuring output meets both domestic and international standards across fabrication shops and industrial supply chains.

FAQs of welding electrode plant in Turkey:

Q: How does the welding electrode plant handle different raw materials?

A: The plant is designed to process a wide range of raw materials, such as mild steel wire, ferro alloys, powders, and specialized chemicals. Its modular construction and integrated powder coating system facilitate the seamless handling and transformation of these materials into high-quality welding electrodes.Q: What is the electrode diameter and length range supported by this plant?

A: This plant supports an electrode diameter range from 2.0 mm to 6.0 mm and lengths between 250 mm and 450 mm, accommodating a variety of welding applications and customer specifications.Q: When is it advantageous to opt for a fully automatic configuration over a semi-automatic one?

A: A fully automatic configuration is ideal for operations seeking maximum production efficiency, minimal manual intervention, and higher consistency in quality. If your facility handles large-scale production up to 10 tons per day, full automation optimizes manpower and reduces operational errors.Q: Where is this welding electrode plant typically installed?

A: The plant is intended for medium to large industrial setups, fabrication shops, and dedicated welding electrode manufacturing facilities, offering both flexibility and scalability for different production environments.Q: What processes does the plant automate, and how does this benefit users?

A: The plants PLC-based intelligent control system automates critical processes such as feeding, coating, drying, and cutting. This reduces manual labor, increases efficiency, and ensures consistent electrode quality, translating into higher productivity and lower operational costs.Q: How much manpower is needed per shift, and what are the plants electrical requirements?

A: Only 2 to 3 personnel are required per shift, thanks to the plants automation and user-friendly controls. It operates efficiently with an electrical consumption of 11 to 15 kW per hour, depending on the model, and requires a 380V/415V, 3-phase, 50-60 Hz power supply.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

கைபேசி number

Email

வெல்டிங் எலக்ட்ரோடு ஆலை உள்ள பிற தயாரிப்புகள்

|

DECCAN DYNAMICS

அனைத்து உரிமைகளும் பாதுகாக்கப்பட்டவை.(பயன்பாட்டு விதிமுறைகளை) இன்ஃபோகாம் நெட்வொர்க் பிரைவேட் லிமிடெட் . உருவாக்கப்பட்டது மற்றும் நிர்வகிக்கப்படுகிறது |