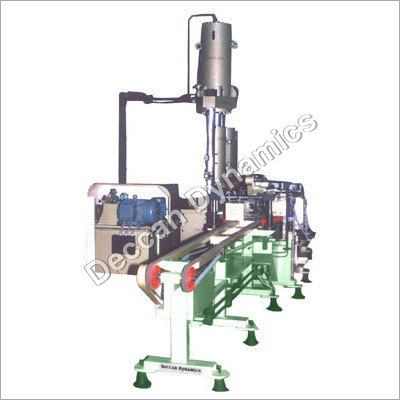

Welding Electrode Extrusion Plant

Product Details:

- Noise Level Low (<75 dB)

- Drive Type Electric

- Material Mild Steel (MS), Stainless Steel Parts

- Size Standard Industrial Size

- Speed Variable, up to 40 RPM

- Machine Type Welding Electrode Extrusion Plant

- Cooling System Water Cooling

- Click to View more

Welding Electrode Extrusion Plant Price And Quantity

- 1 Unit

- 3000000 INR/Unit

Welding Electrode Extrusion Plant Product Specifications

- Variable, up to 40 RPM

- Welding Electrode Extrusion Plant

- Low (<75 dB)

- Electric

- Standard Industrial Size

- Mild Steel (MS), Stainless Steel Parts

- Semi Automatic

- Approx. 3,500 kg

- 500 to 800 kg/hr

- PLC Based Automatic Controls

- Three Phase, 440 V, 50 Hz

- Water Cooling

- Approx. 4,200 mm x 1,350 mm x 2,300 mm

- Ambient to 60C

- Welding Electrode Manufacturing

Welding Electrode Extrusion Plant Trade Information

- 1 Unit Per Month

- 1 Week

- South America, Eastern Europe, Western Europe, Africa, Australia, Middle East, Asia, North America, Central America

- North India

Product Description

We are instrumental in providing our clients a comprehensive range of Welding Electrode Extrusion Plant that is used in welding electrode manufacturing industry for straightening of metal wire used to manufacture electrode. This plant is precisely engineered using the finest quality components and ultra-modern technology as per the set industry norms. Further, offered highly efficient plant available in varied capacities to meet the different needs of clients. We offer this quality tested Welding Electrode Extrusion Plant at market leading price to the clients.

Specifications :

|

Plant Capacity MT/8 Hr.sft |

Extrusion Force (Ton) |

Power (KW) |

Flux Cylinder Capacity (Lt) |

Flux Discharge

cc/Min

|

|

1 |

36 |

2.25 |

3.5 |

800 |

|

3 |

65 |

3.75 |

7 |

2500 |

|

5 |

130 |

11.25 |

15 |

4500 |

|

8 |

225 |

18.75 |

33 |

7000 |

Features ofWelding Electrode Extrusion Plant :

- Superior performance

- Energy efficient

- Robust construction

- Longer service life

Advanced Control System

The plant integrates a state-of-the-art PLC-based automatic control system that ensures consistent quality and operational safety. Operators benefit from precise automation while still retaining manual oversight where necessary, making it ideal for semi-automatic workflows.

Flexible and Robust Production

With a variable speed drive reaching up to 40 RPM and a high production capacity of 500 to 800 kg/hr, this extrusion plant is suitable for both medium and large-scale manufacturing facilities. Its construction using mild steel and stainless steel parts guarantees longevity and robustness.

Efficient Cooling and Low Noise Operation

The integrated water cooling system maintains optimal working temperatures from ambient up to 60C, extending equipment life and ensuring safe, reliable production. The plants design minimizes noise levels, keeping operational sound below 75 dB for a better workplace environment.

FAQs of Welding Electrode Extrusion Plant:

Q: How does the PLC-based automatic control system enhance plant operations?

A: The PLC-based automatic control system streamlines and automates various operations within the plant, improving accuracy, consistency, and efficiency in electrode manufacturing while reducing human error and production downtime.Q: What are the typical applications of this welding electrode extrusion plant?

A: This plant is primarily used in the manufacturing of welding electrodes, catering to industries that require high-quality, mass-produced electrodes for metal joining and fabrication processes.Q: When should the water cooling system be engaged during operation?

A: The water cooling system is typically used throughout the production process, especially when the working temperature approaches the upper limit of 60C, to efficiently dissipate heat generated during extrusion and protect the machinery.Q: Where can this extrusion plant be installed?

A: It is suitable for installation in standard industrial manufacturing settings with access to a three-phase, 440 V power supply. Its size and weight call for solid industrial flooring and adequate space for safe operation and maintenance.Q: What is the process flow of electrode manufacturing in this plant?

A: The plant mixes raw materials, extrudes the coated electrodes using controlled speeds up to 40 RPM, and employs automated PLC controls for precise handling. The electrodes are then cooled, cut to length, and prepared for packaging.Q: How does variable speed benefit the electrode production process?

A: Variable speed operation allows for fine-tuning the extrusion rate to match production targets and electrode specifications, enhancing product quality and enabling flexibility according to different manufacturing requirements.Q: What maintenance practices ensure efficient and reliable plant operation?

A: Regular inspection of the PLC system, timely servicing of the water cooling system, lubrication of moving parts, and routine cleaning of mild steel and stainless steel components are crucial for maintaining long-term efficiency and reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Welding Electrode Plant ' category

|

DECCAN DYNAMICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |