welding electrode plant in Algeria

Price 2500000 INR/ Unit

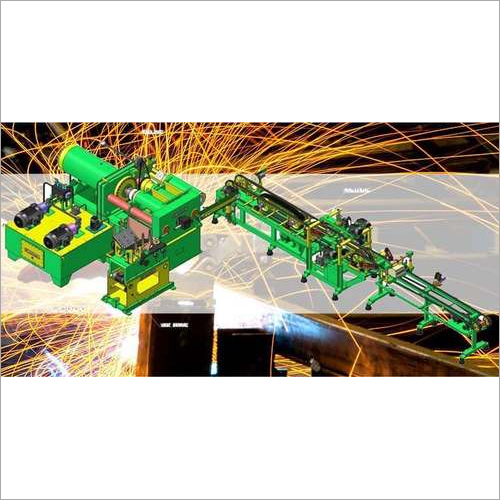

welding electrode plant in Algeria Specification

- Dimension (L*W*H)

- 14500 mm x 1900 mm x 2200 mm

- Power Supply

- Three Phase, 380-415V, 50 Hz

- Size

- Customizable as per requirement

- Usage & Applications

- Manufacturing welding electrodes of different types and sizes

- Noise Level

- Below 75 dB

- Working Temperature

- 5C - 45C

- Weight

- Approx. 6000 kg

- Automation Grade

- Semi-Automatic / Automatic

- Material

- Heavy-duty Mild Steel Construction

- Features

- High productivity, energy efficient, low maintenance, modular design

- Machine Type

- Welding Electrode Production Line

- Cooling System

- Water cooling / Air cooling options

- Speed

- 40 - 100 m/min (adjustable)

- Control System

- PLC Based Panel with Touch Screen

- Production Capacity

- 1000 - 4000 kg/shift

- Drive Type

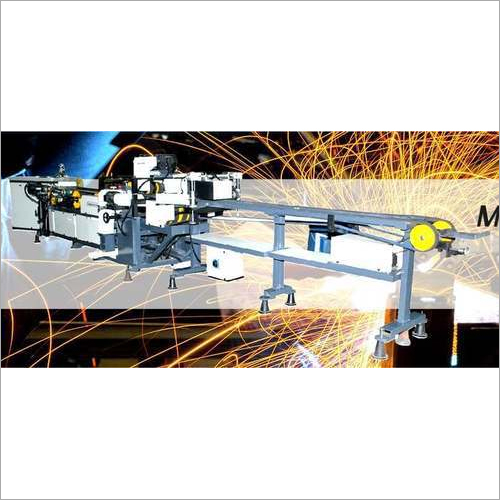

- Electric Motor Driven

- Installation Time

- 30-45 days

- Safety Features

- Emergency stop, Overload protection

- Packaging Type

- Wooden box/As per requirement

- Baking Oven Capacity

- 1000 kg/batch

- Electrode Length Produced

- 250 mm to 450 mm

- Input Raw Materials

- Mild steel wires, Rutile, Iron powder, Binder chemicals

- PLC Brand

- Siemens/Equivalent

- Wire Feeding

- Precision automatic wire feeding

- Operation Mode

- Continuous

- Humidity Range

- Less than 70% RH

- Electrode Diameter Range

- 2.5 mm to 6.0 mm

- After-sales Service

- Available in Algeria

- Conveyor Type

- Roller/Chain type

- Number of Operators Required

- 2-3 persons/shift

- Foundation Required

- Concrete base

- Max. Installed Power

- 27.5 kW

- Electrode Coating Thickness

- 1.0-3.0 mm

- Paint Finish

- Corrosion resistant coating

welding electrode plant in Algeria Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

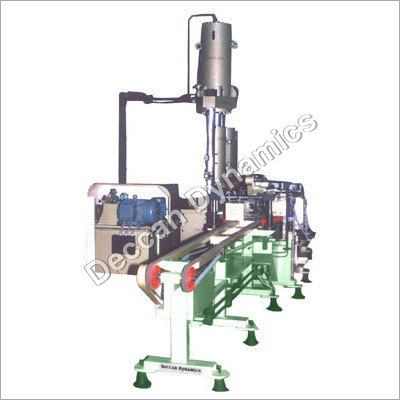

About welding electrode plant in Algeria

Specification- Production Capacity 21000 kg per hour

- Automation Grade Semi-Automatic

- Phase 3 Phase

- Material MS ( Body )

- Power Source Electric

- Voltage 440V

- Surface Finishing Color Coated

- Country of Origin Made in India

- Motor Power 100 HP

Efficient Production with Automation

This electrode production plant leverages semi-automatic or fully automatic operation, powered by advanced PLC control panels with easy-to-use touch screens. The automatic wire feeding and adjustable speed (40 to 100 m/min) enable high productivity and consistent quality for every shift.

Designed for Safety and Reliability

Safety is paramount with integrated emergency stop switches and overload protection systems. Sturdy mild steel construction, corrosion-resistant finishes, and noise levels kept below 75 dB ensure a safe and comfortable working environment. The entire process operates smoothly on a standard three-phase power supply.

Versatile Application and Customization

Capable of handling various electrode types and sizes, this production line accommodates a wide range of welding applications. With customizable machine size and flexible packaging options, the plant adapts seamlessly to unique customer requirements and diverse operational needs.

FAQs of welding electrode plant in Algeria:

Q: How is the welding electrode manufacturing process carried out in this plant?

A: The process begins with raw materialsmild steel wires, rutile, iron powder, and binder chemicalsfed into precision systems. Automated wire feeding shapes electrodes, which are then coated to the specified thickness (1.03.0 mm). Baking ovens process up to 1000 kg per batch, ensuring optimal electrode properties. All functions are monitored and controlled via a PLC-based panel for accuracy and consistency.Q: What range of electrode diameters and lengths can be produced?

A: The plant is capable of producing welding electrodes with diameters ranging from 2.5 mm to 6.0 mm and lengths between 250 mm and 450 mm. Coating thickness can also be adjusted within the 1.03.0 mm range, catering to various welding needs.Q: When is installation completed and after-sales support available?

A: Typical installation requires 3045 days, depending on site preparation and customization. After-sales service is fully available within Algeria, ensuring prompt assistance for maintenance, troubleshooting, and spare parts supply.Q: Where can this plant be installed and does it require special foundation work?

A: The plant can be installed at any location in Algeria with a reliable three-phase (380415V, 50 Hz) power source. It requires a concrete base foundation for stable and vibration-free operation, with flexible layout dimensions to suit different factory spaces.Q: What are the main benefits of using this electrode production line?

A: Key benefits include high productivity (10004000 kg per shift), low maintenance needs, modular design for easy upgrades, energy efficiency, and user-friendly controls. The plant is built for durability with a corrosion-resistant finish, and offers flexible customization to fit diverse business needs.Q: How many operators are needed for each shift, and what is the noise level?

A: Only 23 operators are required per shift due to the high level of automation. The machine operates quietly, with noise levels maintained below 75 dB, resulting in a comfortable working environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Electrode Plant Category

Welding Electrode Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric Motor Driven

Control System : PLC Based Control Panel

Production Capacity : 2000 3000 kg/shift

Speed : Variable, up to 100 m/min

Welding Rod Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric Motor Driven

Control System : PLC Based Control Panel

Production Capacity : 10002000 kg per shift

Speed : 120150 rods/min

Welding Electrode Extrusion Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Control System : PLC Based Automatic Controls

Production Capacity : 500 to 800 kg/hr

Speed : Variable, up to 40 RPM

welding electrode plant in Cape Town

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric Motor Driven

Control System : PLC based control panel

Production Capacity : 1500 2500 kg per shift

Speed : Variable, up to 55 rods/min

|

DECCAN DYNAMICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry