Welding Electrode Plant

3000000 INR/Unit

Product Details:

- Weight Approx. 3500 Kg

- Control System PLC Based Control Panel

- Automation Grade Semi-Automatic / Fully Automatic (as per requirement)

- Cooling System Air/Water Cooled options

- Material Mild Steel, Stainless Steel for specific parts

- Usage & Applications Production of welding electrodes for construction, fabrication, and repair works

- Power Supply 415 V / 3 Phase / 50 Hz

- Click to View more

X

Welding Electrode Plant Price And Quantity

- 1 Unit

- 3000000 INR/Unit

Welding Electrode Plant Product Specifications

- PLC Based Control Panel

- Approx. 3500 Kg

- Semi-Automatic / Fully Automatic (as per requirement)

- Electric Motor Driven

- Mild Steel, Stainless Steel for specific parts

- Air/Water Cooled options

- 415 V / 3 Phase / 50 Hz

- Variable, up to 100 m/min

- Production of welding electrodes for construction, fabrication, and repair works

- 2000 - 3000 kg/shift

- Less than 75 dB

- Standard/Customized as per plant layout

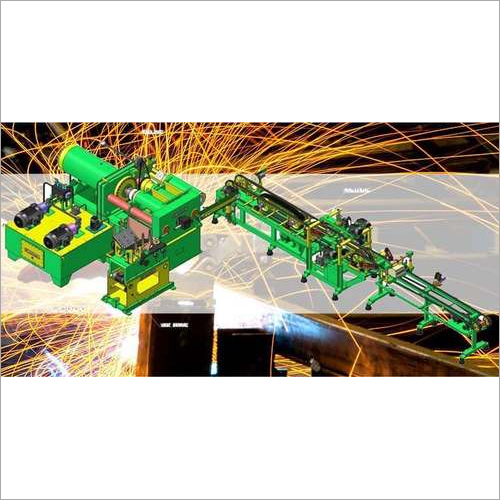

- Welding Electrode Plant

- Approx. 22 x 8 x 8 Feet

- Up to 60C

- High efficiency, robust design, easy to operate, low maintenance

Welding Electrode Plant Trade Information

- 1 Unit Per Day

- 1 Week

- All India

- ISO 9001:2008

Product Description

Indias Leading Welding Electrode Manufacturing Plant in Coimbatore. Deccan Dynamics incorporated in the year 1989. We have emerged ourselves as a manufacturer and exporter of Welding Electrode Plant and Machinery, MIG Wire Plant and many more plants as per international standards and clients requirements.

Features :

- High Performance

- Easy Operation

- Low Maintenance

- Sturdy And Corrosion Resistant.

High Efficiency and Versatile Design

The Welding Electrode Plant delivers efficient electrode production with capacity for up to 8000 kg per batch and a production rate of 20003000 kg per shift. Its robust construction, coupled with mild steel and stainless steel options, offers durability, while the variable speed and automatic wire feeder system ensure versatility for various applications. The plant can be configured as semi-automatic or fully automatic based on project requirements.

Advanced Control and Safety Features

Safety and precision are paramount with a PLC-based control system, allowing operators to manage processes easily. The baking oven operates at up to 60C and maintains noise below 75 dB, ensuring a safe working environment. With adjustable extrusion pressure and operating humidity tolerance up to 85% RH, the plant suits diverse production needs while maintaining quality.

Customizable and User-Friendly Installation

Suitable for both standard and customized layouts, the plants installation is provided by expert technicians to ensure seamless setup. Its energy-efficient design, operating at approximately 25 kW with electric motor drive, minimizes running costs. Air and water-cooled options ensure optimal thermal controls, making this plant a reliable addition to any welding-related manufacturing facility.

FAQs of Welding Electrode Plant:

Q: How does the automatic wire feeder system enhance the operation of the welding electrode plant?

A: The automatic wire feeder system streamlines the production process by efficiently supplying core wire for electrode manufacturing without manual intervention, resulting in higher productivity, reduced labor, and consistent quality across large batches.Q: What types and sizes of welding electrodes can be produced with this plant?

A: The plant supports electrode diameters from 2.5 mm to 5 mm and lengths between 250 mm and 450 mm, making it ideal for various welding applications in construction, fabrication, and repairs.Q: When should the baking oven be utilized during the electrode manufacturing process?

A: The baking oven is used after extrusion to remove residual moisture and ensure proper bonding of flux coating. With a capacity of up to 8000 kg per batch and controlled temperature settings up to 60C, it guarantees uniform drying and high-quality electrodes.Q: Where is installation support for this plant available?

A: Installation services are provided by the supplier and available across India, ensuring that the plant is correctly set up and tailored to the specific plant layout and operational needs of each customer.Q: What are the maintenance requirements for this welding electrode plant?

A: The plant is designed for low maintenance, thanks to its robust build and high-quality materials like mild steel and stainless steel. Routine checks, cleaing, and servicing as per manufacturers guidelines will help maintain optimal performance.Q: How does the PLC-based control panel improve safety and operation efficiency?

A: The PLC-based control panel allows for precise monitoring and adjustment of production parameters, enhancing operational safety, reducing errors, and ensuring reliable and efficient plant management.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Welding Electrode Plant ' category

|

DECCAN DYNAMICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |