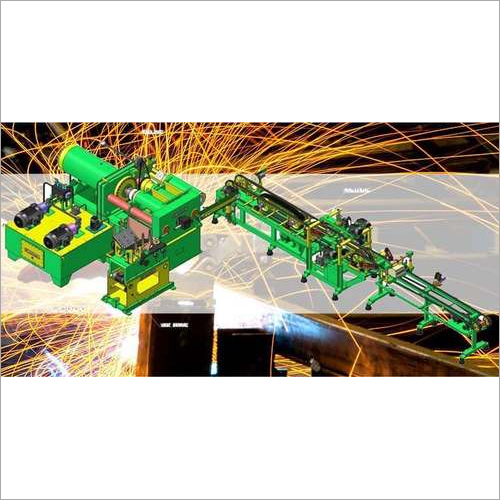

welding electrode plant in Cape Town

Price 2500000 INR/ Unit

welding electrode plant in Cape Town Specification

- Control System

- PLC based control panel

- Working Temperature

- Ambient to 45C

- Dimension (L*W*H)

- 8000 mm x 2200 mm x 2600 mm

- Cooling System

- Air Cooled

- Automation Grade

- Semi-Automatic

- Machine Type

- Welding Electrode Making Plant

- Noise Level

- 80 dB (A)

- Material

- Mild Steel, Stainless Steel (critical parts)

- Usage & Applications

- Manufacture of welding electrodes for industrial and commercial welding

- Power Supply

- Three Phase, 415V, 50Hz

- Drive Type

- Electric Motor Driven

- Weight

- 3800 kg (approx)

- Features

- Robust construction, high output efficiency, low power consumption, precision coating, user-friendly interface

- Production Capacity

- 1500 - 2500 kg per shift

- Speed

- Variable, up to 55 rods/min

- Size

- Standard/Customizable

- Required Operators

- 3-4 per shift

- Rod Cutting Length

- 300 mm, 350 mm, 400 mm, 450 mm

- Coating Thickness Range

- 0.8 mm to 1.6 mm

- Power Consumption

- 18 kW average

- Operating Humidity

- Up to 90% RH (Non-condensing)

- Electrode Diameter Range

- 2.0 mm to 5.0 mm

- After Sales Support

- Available in Cape Town & Surrounds

- Input Raw Materials

- Mild Steel Wire, Flux Ingredients

welding electrode plant in Cape Town Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Months

About welding electrode plant in Cape Town

Specification

- Production Capacity 21000 kg per hour

- Automation Grade Semi-Automatic

- Phase 3 Phase

- Material MS ( Body )

- Power Source Electric

- Voltage 440V

- Surface Finishing Color Coated

- Country of Origin Made in India

- Motor Power 100 HP

Advanced Manufacturing Capabilities

This plant can manufacture a broad spectrum of welding electrodes with diameters from 2.0 mm to 5.0 mm and lengths up to 450 mm. The system's PLC-based control and electric drive ensure precision coating and efficient output rates, enabling users to consistently meet stringent industrial standards.

Designed for Cape Town's Industry

With after-sales support available in Cape Town and its surrounds, our plant is suited for both local manufacturers and exporters. It operates optimally in ambient temperatures up to 45C and humidity up to 90% RH, ensuring reliable performance in varying conditions.

User-Friendly and Efficient Operation

The semi-automatic design reduces the number of operators to just 3-4 per shift, while the user-friendly interface simplifies process management. Robust cooling and low noise levels contribute to an optimal working environment, while flexible sizing options meet different space and capacity requirements.

FAQ's of welding electrode plant in Cape Town:

Q: How does the electrode manufacturing process work in this plant?

A: The manufacturing process begins with raw mild steel wire, which is cut into rods of desired length (300 mm to 450 mm). The rods are then coated with flux ingredients to achieve the required thickness (0.8 mm to 1.6 mm). Using a PLC-controlled system, electrodes are precisely coated and finished, ready for industrial use.Q: What are the main benefits of using this welding electrode plant?

A: Key benefits include high output efficiency (up to 2500 kg per shift), precision in coating, low power consumption (average 18 kW), user-friendly operation, robust construction, and local after-sales support in Cape Town. Its semi-automatic system also ensures reduced labor costs and operational consistency.Q: Where is after-sales support for this machine available?

A: After-sales support is readily available in Cape Town and the surrounding areas. As a manufacturer and exporter, we're dedicated to ensuring reliable maintenance, supply of spare parts, and prompt technical assistance for our local customers.Q: What types of industries can benefit from this electrode plant?

A: This plant is ideal for manufacturers producing welding electrodes for industrial fabrication, construction, shipbuilding, and commercial welding enterprises. It's also well-suited for exporters and suppliers needing customizable outputs and high production capacity.Q: Can the plant accommodate different rod sizes and coatings?

A: Yes, the plant offers customizable rod cutting lengths (300 mm, 350 mm, 400 mm, or 450 mm) and supports electrode diameters from 2.0 mm to 5.0 mm, with adjustable coating thickness between 0.8 mm and 1.6 mm to meet various customer specifications.Q: What is the typical power supply required for this plant?

A: The plant runs on a standard three-phase power supply (415V, 50Hz) with an average power consumption of 18 kW, making it suitable for industrial environments in Cape Town and compatible with common electrical infrastructures.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Electrode Plant Category

Industrial Welding Electrode Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Cooling System : Air/Water cooled

Automation Grade : SemiAutomatic/Automatic

Machine Type : Welding Electrode Production Plant

Material : Mild Steel structure with stainless steel contact parts

Welding Electrode Plant

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Air/Water Cooled options

Automation Grade : SemiAutomatic / Fully Automatic (as per requirement)

Machine Type : Welding Electrode Plant

Material : Mild Steel, Stainless Steel for specific parts

Welding Electrode Production Plant

Price 3000000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Air Cooling

Automation Grade : SemiAutomatic

Machine Type : Welding Electrode Production Plant

Material : Mild Steel & Stainless Steel

welding electrode plant in Tanzania

Price 2500000 INR / Unit

Minimum Order Quantity : 1 Unit

Cooling System : Water Cooled

Automation Grade : SemiAutomatic

Machine Type : Welding Electrode Plant

Material : Mild steel, stainless steel, and alloy

|

DECCAN DYNAMICS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry